I did a lot of local excursions the past 3 days – Jerusalem, Tel Aviv, Herzliya and Haifa. For some reason, the conversations with 2 prospects had to do with refrigerators. I do not know if this is Freudian or not, considering the hot weather of July in Israel.

The conversations about refrigerators had to do with storing drugs / investigational product at the proper temperatures.

A Temperature excursion is a deviation

The great thing about not coming from the clinical trials space is that you are always learning new things.

Yesterday – I learned that a Temperature excursion is a deviation from given instructions. It is defined in the WHO Model Guidance as “an excursion event in which a Time Temperature Sensitive Pharmaceutical Product (TTSPP) is exposed to temperatures outside the range(s) prescribed for storage and/or transport.

Storing drugs at the proper temperature is part of GCP. Here is an SOP for Monitoring and Recording Refrigerator & Freezer Temperatures

1 Introduction All refrigerators and freezers used for the storage of Investigational Medicinal Products (IMPs) must be temperature controlled, and continuously monitored and maintained within the appropriate ranges as defined by the protocol. ICH GCP Principle 2.13 states “Systems with procedures that assure the quality of every aspect of the trial should be implemented.”

Moving on:

5 Procedure

Current maximum/minimum thermometers must be monitored as a minimum at least once on a daily basis on all working days, and recorded legibly on the temperature monitoring log.

The digital maximum/minimum thermometer –

□ Should be read from the outside of the refrigerator without opening the door.

□ Have an accuracy of at least +/- 1 oC.

□ Be able to record temperatures to one decimal place.

□ Be supplied with a calibration certificate.

□ Have the calibration check on an annual basis.

Temperature logs should be kept close to the refrigerator/freezer (but not inside) to which they relate for ease of reference, and should be clearly identified as relating to that appliance.

A separate temperature record must be kept for each fridge/freezer. (The use of whiteboards as a method of logging results is not acceptable.)

It is good practice to record the temperature at a similar time each day e.g., first thing in the morning before the refrigerator door is opened for the first time. This will allow review of trends in results recorded; help highlight any changes in temperatures recorded and deviation in refrigerator performance.

There is a lot of manual work involved looking at refrigerators

I believe a study monitor will spend 20’/day checking logs of refrigerator temperature readings. When you add in time for data entry to the site coordinators – that’s another 20’/day and then you have to multiply by the number of sites and refrigerators. This is only the reading temperatures and capturing data to the EDC part of the job. Then you have to deal with queries and resolving deviations.

For something so mundane (although crucial from a medical research perspective), its a lot of work. The big problem with using study monitors to follow temperature excursions is that the site visits are every 1-3 months. With the spiralling costs of people, the site visits are getting less frequent.

This means that it is entirely plausible that patients are treated with improperly stored drugs and the deviation is undetected for 3 months.

Whenever I see a lot of manual work and late event detection, I see an opportunity.

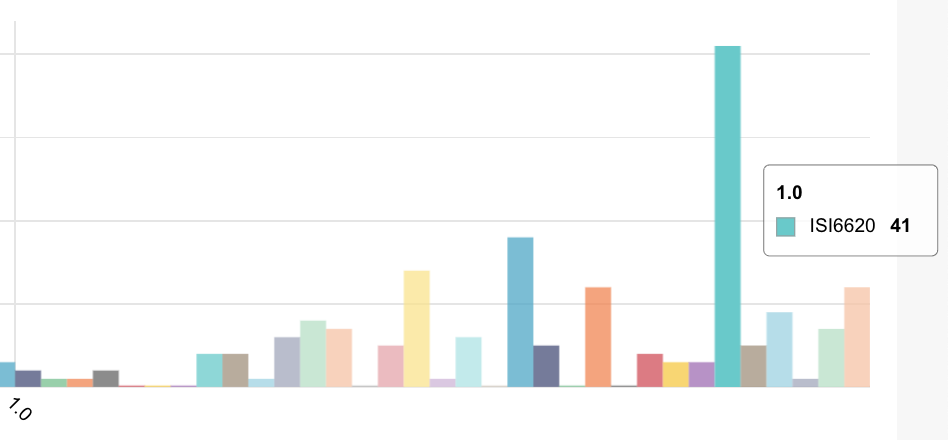

It seems that there are a few vendors doing remote monitoring of refrigerators. A Polish company from Krakow, called Efento has a complete solution for remote monitoring of refrigerators storing investigational product. It looks like this:

What is cool (to coin a pun) about Efento is that they provide a complete solution from hardware to cloud.

The only thing missing is calling a Flask API to insert data into the eCRF for the temperature excursions.

Once’s we’ve got that, we have saved all of the study coordinators and study monitors time.

More importantly, we’ve automated an important piece of the compliance monitoring puzzle – ensuring that temperature excursions are detected and remediated immediately before its too late.